How to Design and Make a Wood Carving Knife

but today I will show you how to make a wood carving knife with a minimum of tools.

This knife is perfect for carving the shrink cup

This knife is perfect for carving the shrink cup

Step 1: Tools Needed

To make this instrucable you only need simple hand tools that most of you already have.

You need a hammer, a saw, a file, a vice, an ax and a knife.I also use a froe and a metal ruler that is nice to have but you can do with out them.

If you don't have a froe use a big knife or a ax to split the wood.

And as a substituted for a metal ruler use the backside of a saw.

Step 2: The Knifeblade

Of course you need a good knifeblade, I like the ones from Frosts Mora. They are cheap and very sharp. The ones I use in this instructable are KB120 and KB106. They are laminated blades with a very hard center and soft iron on the sides. Making the edge durable without making the blade fragile.

The blades are slim, making them ideal for any kind of carvingStep 3: The Wood for the Handle

I use green cherry wood for the handle. By using fresh/green wood I can hammer the blade directly into the handle. That way I don't need to drill holes for the blade, and there is no need for glue.

Other suitable wood for this ; Birch, Red Alder, Linden, Apple, Pear

Red Alder can even be used when dry, but the others need to be green.

Step 4: Prepering the Knifeblade

To have the option to pound the cutting edge into the handle you first need to record the tang. The tang should be straight similar to a nail, not wedge molded like it is from the creator. It you leave the tang wedge molded the handle will part.

I utilize a hand document to carry out the responsibility. In any case, in the event that you have a seat processor you can utilize that. Simply watch your fingers and that the edge don't get to hot.

Likewise cut the tang into length, it should be 5-6cm long. At the point when you have cut the tang record the end so it is level.

Step 5: Prepering the Wood

Cut a 15cm thick cut of your log. Split it a couple of times, and with the hatchet generally cut the handle into shape.

Presently fine shape the end that you intend to pound the sharp edge into. At the point when the sharp edge initially sits into the wood it is difficult to work that region without harming the edge and the edge of the cutting blade.

Step 6: Hammer the Blade Into the Handle

This part are somewhat troublesome so relax and don't surge it. With care and persistence you will have the option to do it.

First cinch the sharp edge tight in the bad habit. Utilize delicate jaws produced using elastic, copper or other delicate metals so you don't harm the sharp edge.

Presently place the idea about top of the tang, and with firm and controlled strokes drive the tang into the handle. All the time you should be certain that the tang gos straight into the handle. To begin with, when the tang's not to long into the handle you can address the edge. Be that as it may, at that point it stalls out. In the event that the cutting edge misunderstands in there are taking note of else to do than split the handle, evacuate it and start from the very beginning.

At the point when the tang are completely gone into the handle this progression is finished. The cutting edge presently sits firm in the handle and you won't be capable for evacuate it again without breaking the handle.

Step 7: Designing the Handle

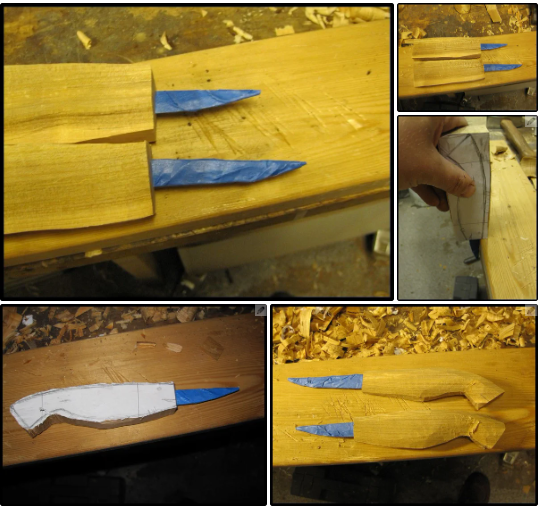

Now take some paper and draw the shape of the blade and the handle.

When you design a handle you need to think of it as a fish. The fish have 3 parts, the head, the stomach and the tail.

1: start by dividing your handle into 3 parts.

2: Now draw a fish in it.

3: Can you see the handle inside the fish?

4: Continue until you have converted your drawing of a fish into a handle.

5; draw the handle from the side and from the top.

6: glue the drawing onto the handle.

When you design a handle you need to think of it as a fish. The fish have 3 parts, the head, the stomach and the tail.

1: start by dividing your handle into 3 parts.

2: Now draw a fish in it.

3: Can you see the handle inside the fish?

4: Continue until you have converted your drawing of a fish into a handle.

5; draw the handle from the side and from the top.

6: glue the drawing onto the handle.

Step 8: Shaping the Handle

Before you start for shape the handle you will cover the edge with tape. To secure the cutting edge and your fingers. I use concealing tape that is anything but difficult to get of when the blade is done.

Presently begin removing the wood outside the drawing. In the event that your talented enough you can begin with a hatchet to do the unpleasant forming, and afterward utilizing the blade for the last cutting.

When your have sliced right to the line of your attracting begin to adjust the edges. At the point when your removing, exceptionally when adjusting the edges you despite everything need to consider a fish. The handle should be round and smooth like a little trout in the water.

Here is a film telling the best way to shape the handle with the hatchet. Sorry about the camera edge, possibly I need a tripod :- )

0 تعليقات